Industry News

NEWS

The Critical Role of the EGR Line in Modern Engine Efficiency

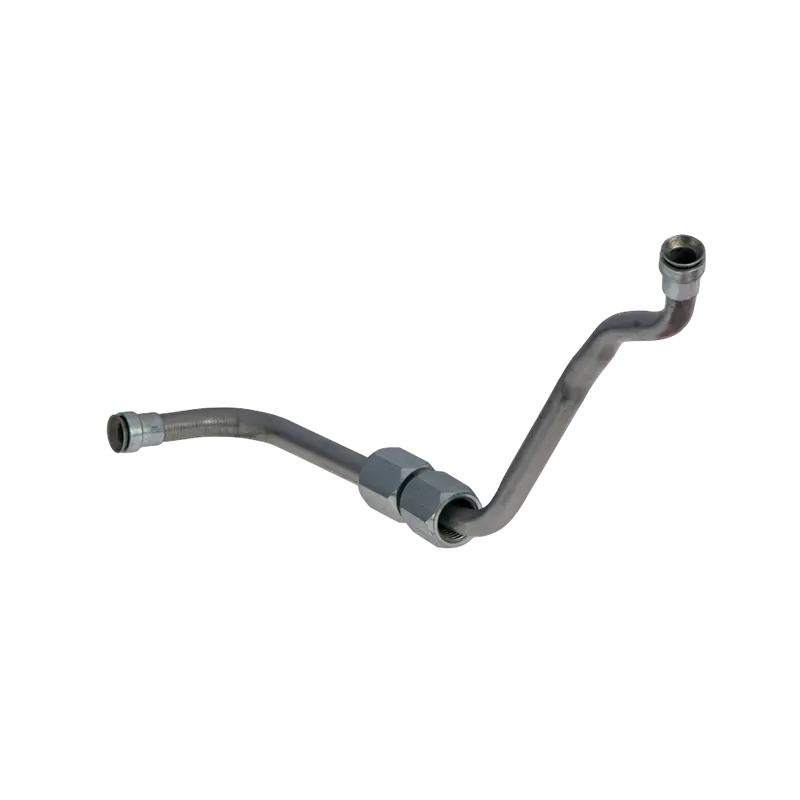

In the push for cleaner automotive technology, the Exhaust Gas Recirculation (EGR) line serves as a vital bridge between the exhaust manifold and the intake system. Its primary function is to reroute a precise portion of inert exhaust gases back into the combustion chamber. By doing so, it lowers the peak combustion temperature, which directly inhibits the formation of Nitrogen Oxides (NOx)—one of the most harmful pollutants.

A high-performance EGR line must do more than just transport gas; it must withstand extreme thermal cycling. Exhaust gases exiting the manifold can reach temperatures exceeding 650°C (1,200°F). If the EGR line is compromised by cracks or carbon buildup, the engine's Control Unit (ECU) will struggle to balance the air-fuel ratio, leading to a noticeable drop in power and a spike in emissions.

Material Durability: Why Stainless Steel and Corrugated Designs Prevail

The environment inside an EGR pipe is incredibly hostile. It is subjected to corrosive exhaust condensates, including sulfuric and nitric acids, alongside intense vibrations from the engine block. To ensure a service life that matches the vehicle’s longevity, premium EGR lines are typically constructed from 304 or 321-grade stainless steel.

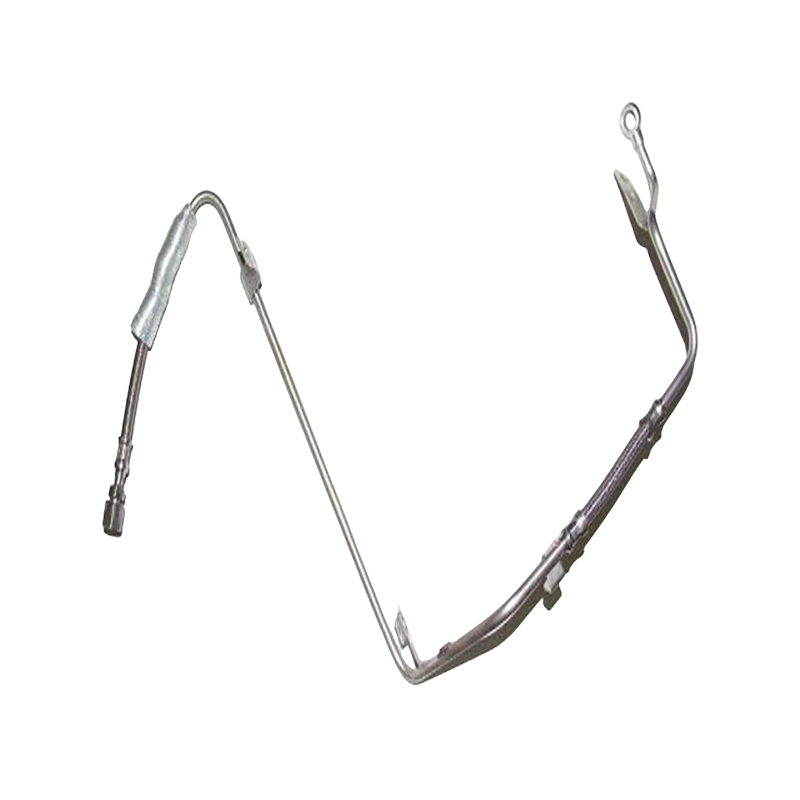

The Advantage of Corrugated Flex Sections

Modern EGR lines often feature a "bellows" or corrugated section. This is not merely an aesthetic choice; it allows the pipe to absorb thermal expansion and engine harmonics without fracturing at the mounting flanges. Without this flexibility, the rigid connection between the hot exhaust manifold and the relatively cooler intake manifold would eventually snap due to differential thermal expansion.

| Feature | Premium Stainless EGR Line | Standard Low-Carbon Steel |

|---|---|---|

| Oxidation Resistance | Excellent (Up to 800°C) | Poor (Risk of Flaking) |

| Vibration Fatigue Life | High (Flex-Bellows Integrated) | Low (Prone to Cracking) |

| Internal Carbon Adhesion | Low (Mirror-Polished ID) | Moderate (Rough Surface) |

Signs of EGR Line Failure: What Every Driver Should Know

EGR lines are prone to a specific type of failure: carbon clogging. Over time, soot from the exhaust mixes with oily vapors in the intake, creating a thick, tar-like substance that chokes the pipe.

- Engine Knocking (Ping): If the EGR line is blocked, combustion temperatures rise too high, causing pre-ignition or "knocking."

- Rough Idle: A cracked EGR line acts as a vacuum leak, introducing unmetered air into the engine.

- Failed Emissions Test: High NOx levels during an inspection are almost always linked to a malfunctioning EGR circuit.

- Reduced MPGs: Inefficient combustion forces the engine to burn more fuel to maintain cruising speeds.

Installation and Maintenance: Ensuring a Gas-Tight Seal

Replacing an EGR line is a precision task. Because it carries high-pressure exhaust, the seals at both ends must be perfect. Most systems use multi-layer steel (MLS) gaskets or high-temperature O-rings. During installation, it is crucial to clean the mounting surfaces on the manifold to prevent "bypass leaks" that can melt nearby plastic components.

For diesel owners, a proactive cleaning of the EGR line every 50,000 miles can prevent the need for a full replacement. Using specialized carbon solvents can dissolve the buildup and restore the intended flow rate. However, if the pipe shows signs of "blueing" (a sign of extreme overheating) or visible external pitting, a complete replacement is the only safe option to avoid Turbocharger damage from debris.

Future Trends: EGR Lines in the Era of Euro 7 Standards

As global emission standards like Euro 7 and EPA 2027 become more stringent, the role of the EGR line is expanding. We are seeing the rise of Low-Pressure EGR (LP-EGR) systems, where the gases are pulled after the Diesel Particulate Filter (DPF). This means the EGR line must now handle cleaner, but cooler gases that are more prone to condensation and "acid rain" inside the pipe.

Modern EGR lines for these systems are now being engineered with internal anti-corrosion linings to combat this new chemical challenge. By choosing an EGR line designed with these modern stressors in mind, fleet operators can ensure their vehicles remain compliant and efficient over millions of collective miles.

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ?NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English Espa?ol

Espa?ol